A subdivision to help you maximize your hydraulic equipment's reliability

Description

Optimizing your production journey

Fluentis differentiates itself by being more than a lab service, it’s a true partnership with our customers to identify reliability improvements and cost effectiveness. We tailor our approach to your needs.

To access your account or to review results please login.

Services

Optimizing your production journey

Our approach is based on total fluid management. meeting with our customers for a plant survey to identify the specific needs and concerns. We provide you with a comprehensive plan for your oil analysis schedule, we can assist you in training your resources for sampling or we can provide you with the technical staff to withdraw samples for you. We can install the sampling points to facilitate your sampling withdrawals. Once your analysis reports come in we can assist you in interpreting those results and provide you with an action plan to address any abnormal results. Our approach includes a regular tracking of the health of your equipment and critical components with improvement proposal with a high return on investment. We have experts available to support your in-plant training needs.

01.

Oil Analysis programs

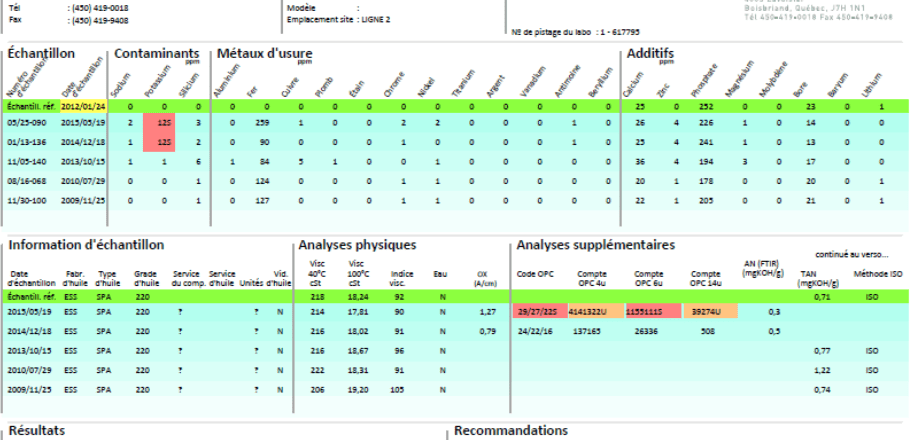

Information is the key to great decision making. We offer a comprehenisve analysis program to get a complete overview of the health of your equipments and critical components. We set up goals to improve your sample results and work with you to get the most out of your oil analysis.

02.

Total Fluid Management

Our approach focuses on gains in productivity and a reduction of maintenance costs. We go beyond the sample results and we help you identify the source and give you the tools to protect your critical components before failure.

03.

Process and plant audits

Our plant audits include the complete picture of your filtration applications, identifying weaknesses and providing you with solutions focusing on inventory optimization and overall cost reduction.

04.

Training

Our experts are available for training tailored to your needs. For individuals, small groups or larger groups of employees, we have the ressources to provide training onsite with your equipment and processes in mind.

Q&A

We got answers to your questions

Here, you will find comprehensive answers to some of the most commonly asked questions regarding our services. Please do not hesitate to contact our support team should you have additional questions. We are committed to providing you with solutions to address your needs.

Can Fluentis take care of sampling and managing the calendar?

Yes, we have dedicated trained resources that can come to your facility and take samples from your critical equipment per the schedule setup on a calendar.

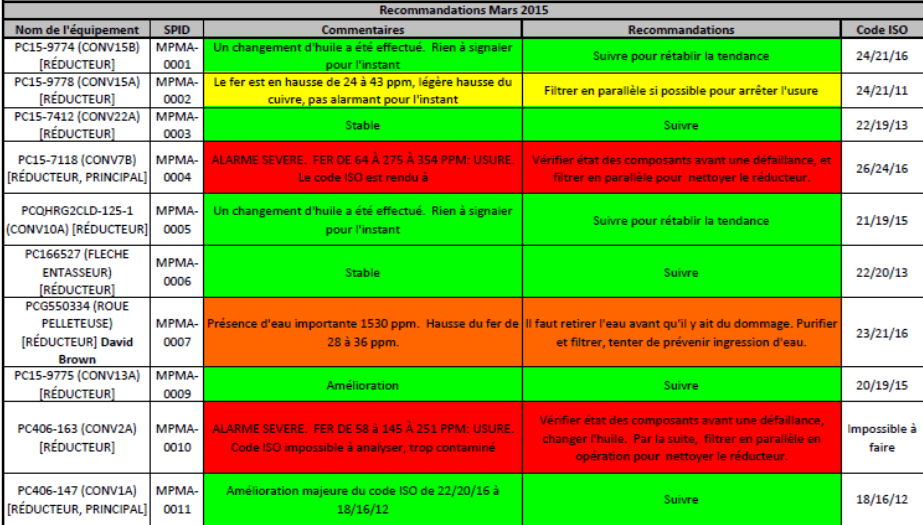

Do you provide support for interpretation?

Yes, we have experienced experts that can read your report and provide very specific actions to correctly maintain the cleanliness of your fluids per your equipment’s requirements.

Can you send a personal report after each sampling run to assist our people with taking the specific actions needed to clean the oil?

Yes, our experts will schedule time with your team to assist them with interpreting the reports and setting cleanliness goals using the ISO 4406 standards.

We are using new oil from the container, why do we need to filter it?

New oil is not clean oil! a common misconception among maintenance and reliability personnel is that new oil purchased is clean enough for immediate use. New oil from containers or bulk deliveries contains 2 to 20 times the amount of particles acceptable for most equipment.

How long will it take to achieve my cleanliness targets for my equipment?

Achieving your cleanliness targets is not an overnight process, but it can lead to major extensions of machine life and oil service life. Each situation is different and depends on your specific application, we typically see immediate results within hours/days with targets met in 1 to 4 weeks. However, ongoing maintenance is essential to extending the life of your equipment and minimizing downtime.

Contact us

We tailor solutions to meet your needs

How can we help you achieve your goals and objectives? Our knowledgeable team of fluid management experts and hydraulic design engineers are available to answer questions about your specific application and provide you with an action plan with recommended solutions to address your needs. Connect with a member of our team by calling 450-419-0018 or email us at info@fluentis.ca.