Pulp and Paper

Hydralogie is dedicated to fostering the growth of our pulp and paper customers by providing advanced filtration products, oil purifiers, and fluid condition monitoring equipment. These innovations are specifically designed to increase machine uptime, reduce maintenance costs, and boost production capacity.

Asset protection within the Pulp and Paper Industry

Industry Leading solutions delivering optimal results

Contamination is an undeniable fact in mill systems. The pulp and paper industry requires a comprehensive approach to maximizing equipment performance and optimizing the production process. Pulp and paper companies require machinery and equipment that can deliver the right control and maintenance of fluids at the desired operating conditions. From hydraulics to lubrication, recycled waters and chemicals to boiler feed water, the operation of a pulp and paper mill is improved by the proper selection of filtration technologies that ensure a consistent level of contamination control throughout the process.

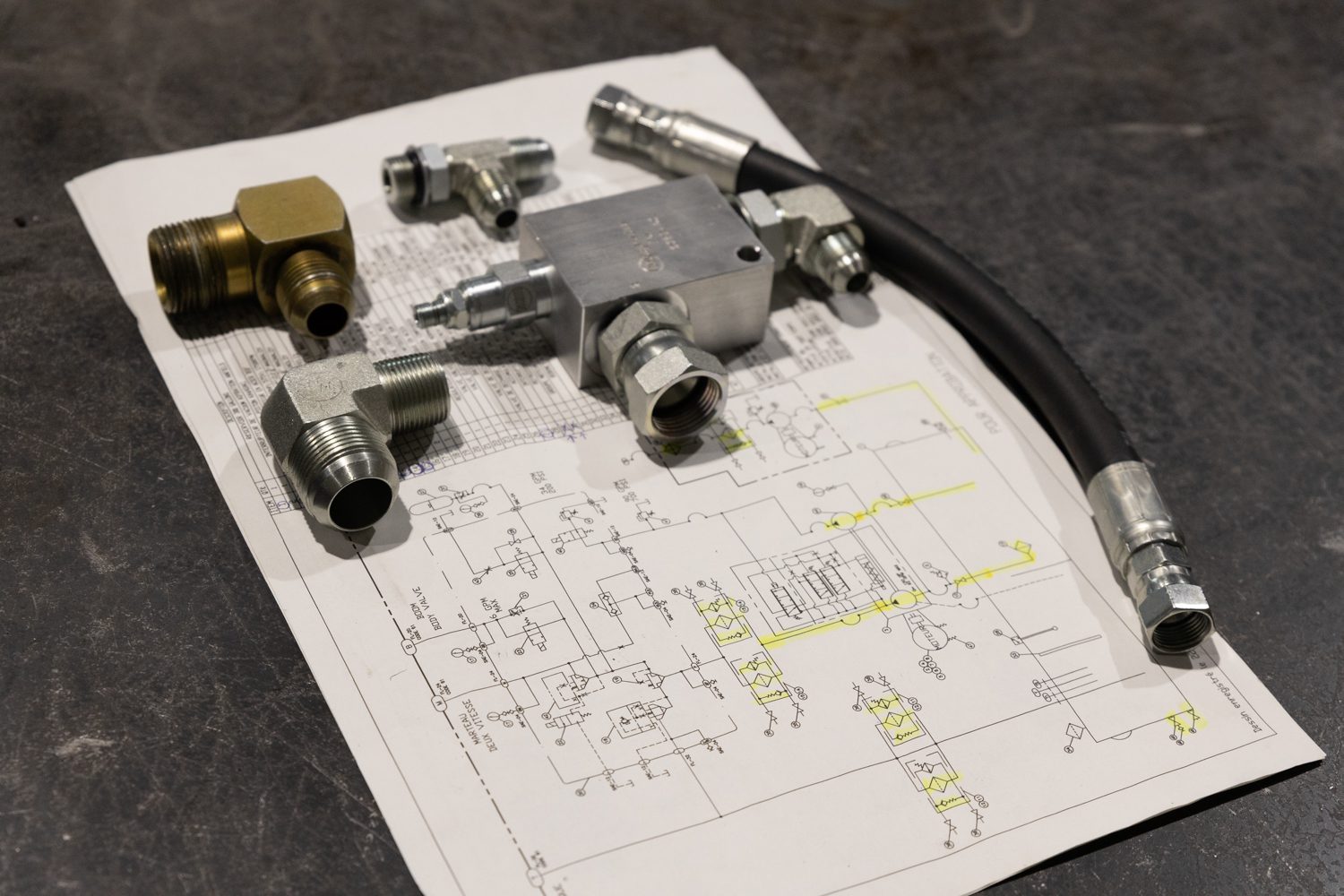

A proactive maintenance strategy with filtration solutions from Hydralogie can immediately decrease unplanned equipment failure and extend the operating life of machines. We can design a preventative maintenance program that includes an oil sampling schedule and analysis on all critical equipment tailored to your operation. We can train your team to execute the plan, analyze the data and take specific actions to maximize the performance of your equipment and extend equipment life.

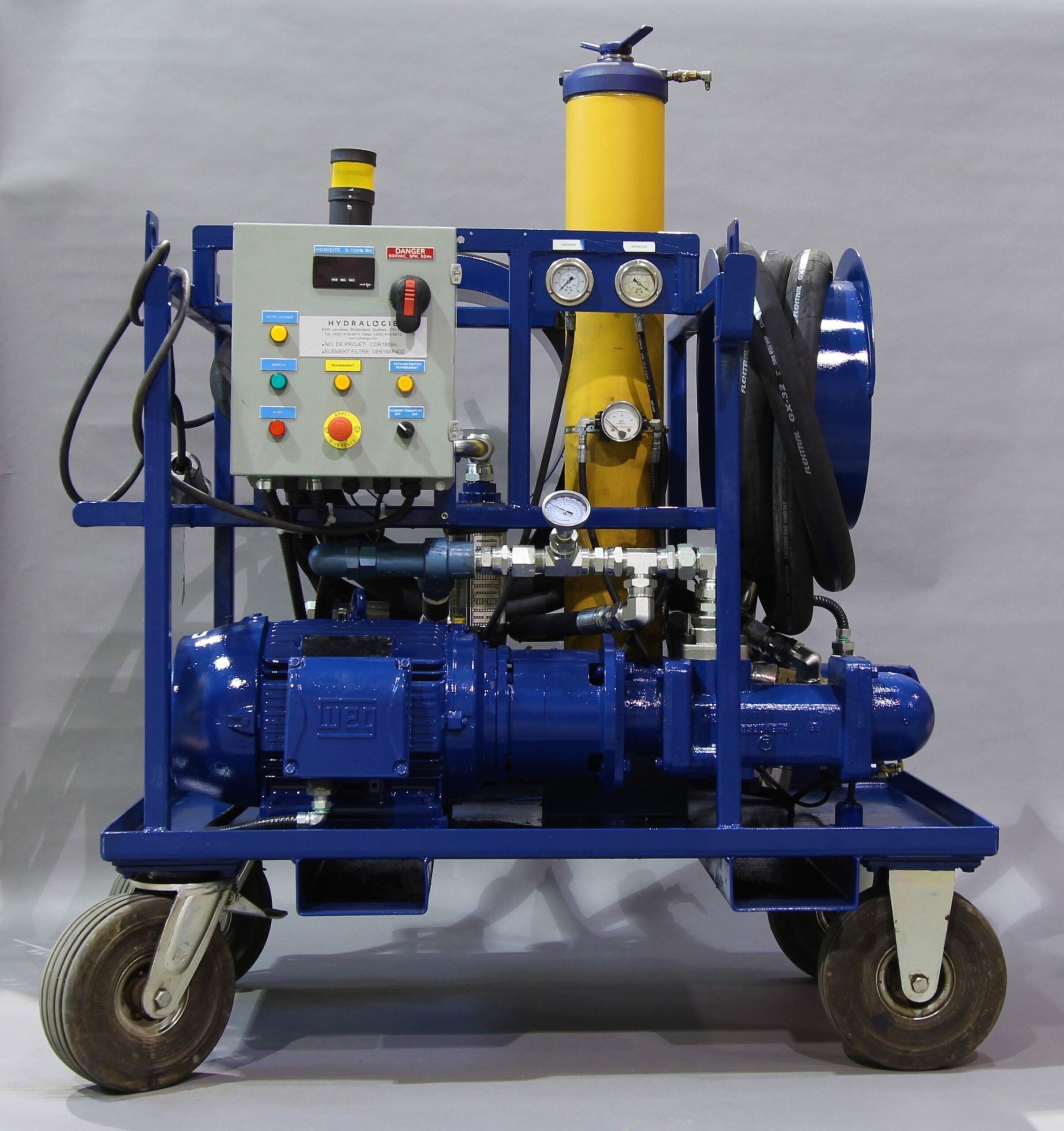

We offer the ultimate in Hydraulic & Lube Oil Filter Performance available for low, medium or high-pressure systems for all viscosities and all operating temperatures, protecting and extending equipment lifespan with Pall SUPRALON TM, CORALON TM, ATHALON TM and ULTIPLEAT ® SRT Filtration. When specifying a hydraulic filter, consider the system’s cleanliness requirements, operating pressure, flow rate, and the filter’s dirt-holding capacity. We also offer complete solutions in offline filtration, commonly referred to as kidney loop systems, which filter oil in a stand-alone system, allowing for precise control of flow and pressure. Systems are sized according to oil volume, viscosity, flow rates and the types of contamination that needs to be removed. Systems are available to rent or purchase depending on your budget constraints.

Water plays a vital role in pulp and paper production, from recycled waters and chemicals to boiler feed water, the operation of a pulp and paper mill can be improved by the proper selection of filtration technologies. Process filters are used to remove impurities, such as algae or sediments, from process water or machine coolant, ensuring the proper operation of equipment and reducing the risk of corrosion or scaling.

Consult with one of Hydralogie’s fluid experts to select the most suitable solution for your applications.