Sampling equipment and reservoir accessories

Your reservoirs are exposed to airborn contamination or moisture. We can provide you with breather filters to prevent atmospheric or airborne contamination and moisture from entering your hydraulic reservoirs and systems.

Suppliers

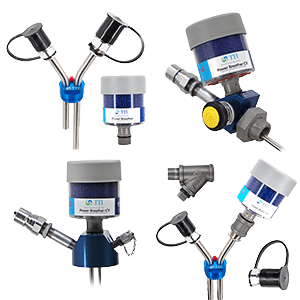

Reservoir Air Breathers

In hydraulic systems, the presence of solid particulates can cause significant damage to system components and severely impact system performance. For this reason, industry professionals integrate reservoir breather filters—also referred to as air breather filters—into their hydraulic equipment to prevent airborne materials from entering through the reservoir.

Breathers are designed to filter out harmful moisture, oil mist, and solid particles before they can enter the hydraulic system. This helps maintain optimal cleanliness levels and prolong the life of the hydraulic fluid.

Desiccant Breathers

Due to the contamination of water and oil in machinery, issues such as the depletion of additives, oil oxidation, corrosion, and rust can occur over time, reducing the service life of your equipment. A desiccant breather installed on equipment filters out debris and moisture, preventing the entrance of contamination and extending the service life of machines. Typical application categories are mining equipment, farm equipment, construction vehicles, paper mills, or any other industrial application.

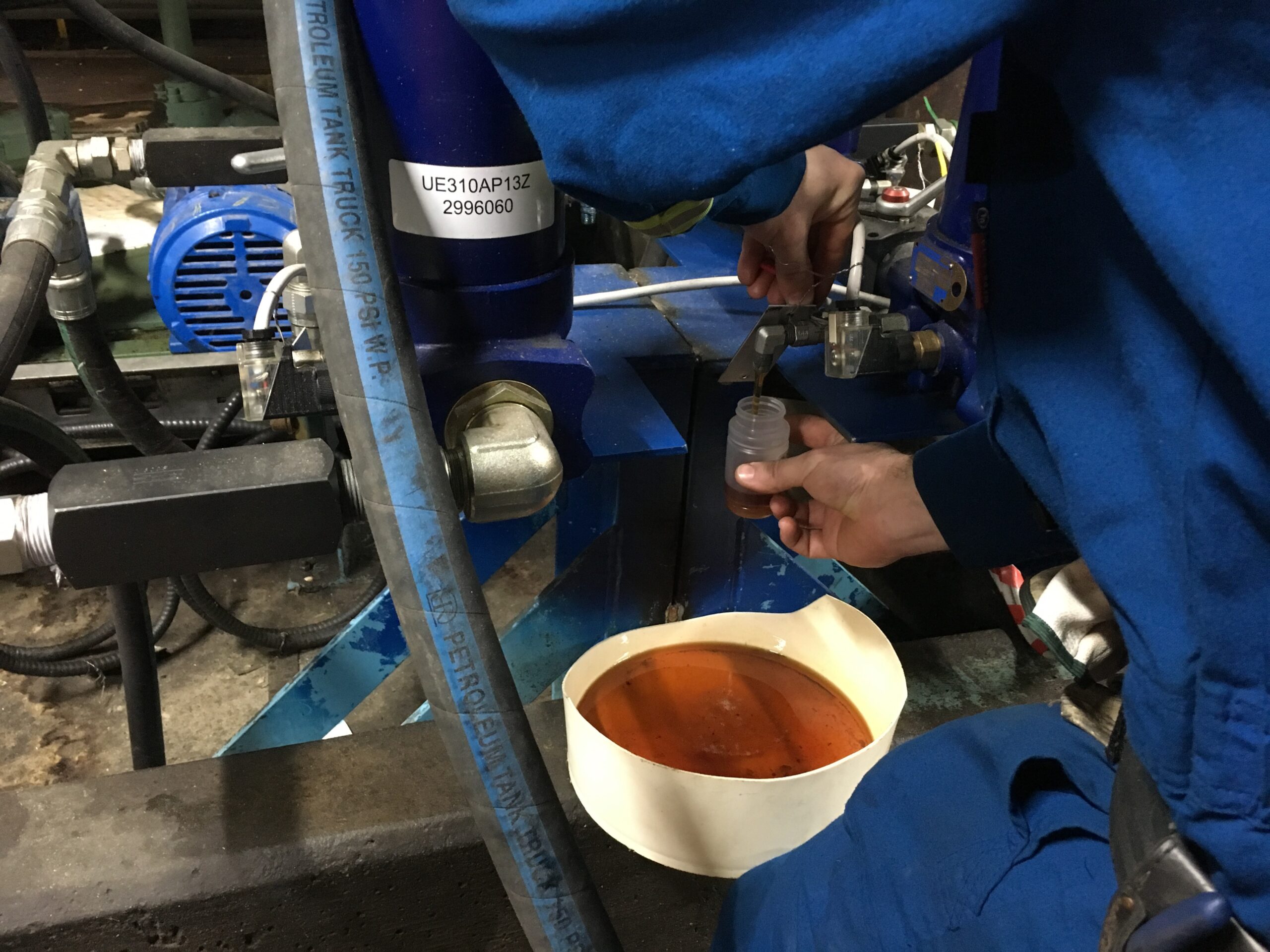

Reservoir sampling kits

Oil analysis is dependent on the small oil sample submitted to the lab. This sample must represent the often very large volume within the entire system. To provide the most complete picture of operating conditions it must accurately reflect a variety of characteristics. This might include the development of critical wear elements, potential varnish contamination or the depletion of a key additive.

Dedicated oil sampling valves make it possible to take reliable oil samples safely, while the equipment is running. This ensures that the sample is a direct representation of the equipment’s condition. The sampling valves are installed into the equipment, ensuring each active oil sample comes from the same spot, every time.

Lubricant handling containers

Poorly stored fluids can become contaminated and will lead to accelerated component wear and robs equipment of efficiency.