Mining

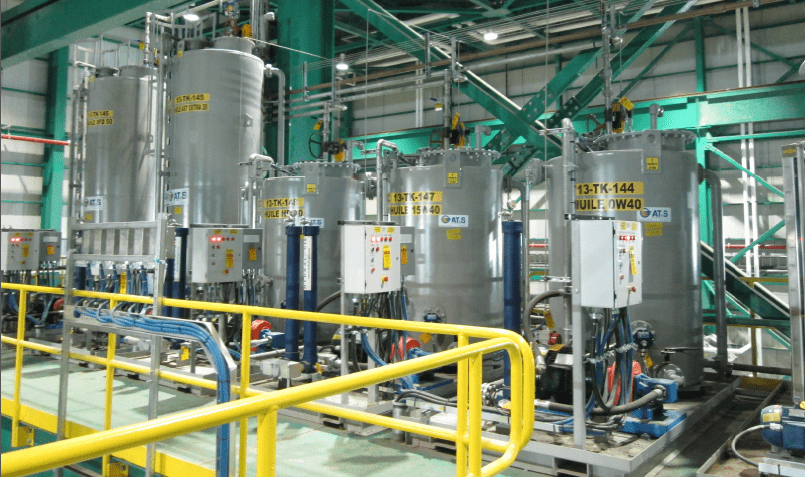

Reducing operating costs and extending the life of mining equipment through effective fluid management programs. The mining business is highly competitive, demanding cost-effective solutions to survive. Ensuring reliability and minimizing downtime of expensive heavy machinery is crucial. Effective filtration of lubricant systems is essential for continuous operations and extending machinery life.

Mining

A full line of hydraulic and Lube oil filtration solutions that maximize ROI and direcly impacts your profitability.

Maintaining mining equipment presents several significant challenges due to the harsh and demanding conditions in which these machines operate. The equipment is subjected to extreme stress, including heavy loads, vibrations, and exposure to dust and moisture. This environment accelerates wear and tear, leading to frequent breakdowns causing significant unplanned downtime, disrupting operations and leading to substantial financial losses. Our hydraulics and lube oil filtration solutions delivers cleanliness performance that reduces the frequency of scheduled maintenance, improves reliability and extends the life of capital equipment.

Most operations operate in remote and climatically hostile environments, which can complicate maintenance efforts. Obtaining spare parts can be difficult and time-consuming, leading to extended downtime when equipment fails. To complicate matters, there is often a shortage of skilled technicians who are capable of maintaining and repairing complex mining equipment. A proactive maintenance strategy with filtration solutions from Hydralogie can immediately decrease unplanned equipment failure and extend the operating life of machines. We can design a preventative maintenance program that includes an oil sampling schedule and analysis on all critical equipment tailored to your operation. We can train your team to execute the plan, analyze the data and take specific actions to keep your equipment running.

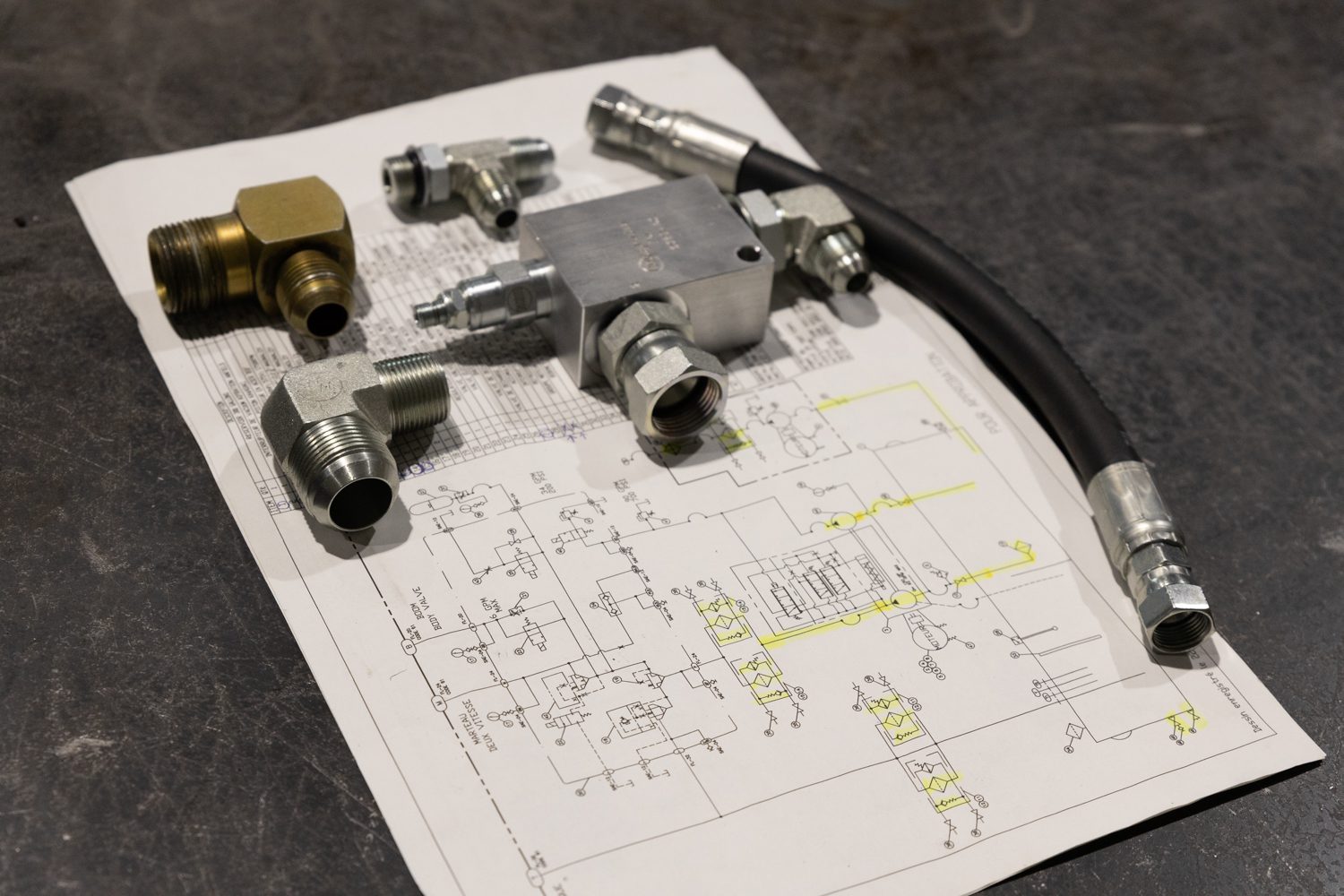

We offer the ultimate in Hydraulic & Lube Oil Filter Performance available for low, medium or high-pressure systems for all viscosities and all operating temperatures, protecting and extending equipment lifespan with Pall SUPRALON TM, ATHALON TM and ULTIPLEAT ® SRT Filtration. When specifying a hydraulic filter, consider the system’s cleanliness requirements, operating pressure, flow rate, and the filter’s dirt-holding capacity. We also offer complete solutions in offline filtration, commonly referred to as kidney loop systems, which filter oil in a stand-alone system, allowing for precise control of flow and pressure. Systems are sized according to oil volume, viscosity, flow rates and the types of contamination that needs to be removed. Systems are available to rent or purchase depending on your budget constraints. Consult with one of Hydralogie’s fluid experts to select the most suitable solution for your applications.

Water plays a vital role in mining. Large volumes of water can be consumed every day within the mining process. Optimizing the use and filtration of fresh mining water is a primary concern. Process filters are used to remove impurities, such as algae or sediments, from process water, ensuring the proper operation of equipment and reducing the risk of corrosion or scaling. Our industrial water treatment solutions minimize operational downtime and exceed water cleanliness criteria.